CFB Boilers

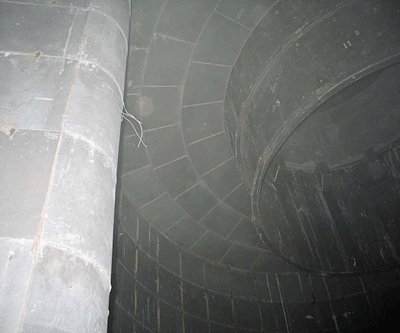

Sheffield Refractories has worked in very close co-operation with AG Port Oy from Finland to develop the latest generation of Monolithic Materials and innovative Installation Techniques for lining CFB Boilers.

Seven years ago AG Port contacted Sheffield Refractories with a request to develop materials specifically designed for CFB Boiler applications. Traditionally, Refractory suppliers have tended to offer products from their standard material list, selecting the best fit option. AG Port was not satisfied with this approach. They highlighted the fact that the conditions within a CFB Boiler are unique in terms of the characteristics they require from a Refractory Lining. The temperatures within these units are comparatively low and the refractory lining can be required to withstand extreme abrasion and alkali attack at relatively low operating temperatures. Probably 75% of all refractories are used within the Steel Industry so naturally many Refractory suppliers focus their attention towards the Steel Industry. As a result smaller markets such as the CFB Boiler Industry can be overlooked. Sheffield Refractories took up the challenge offered by AG Port and developed a range of products with extreme Abrasion Resistance, (up to 4 times better than an Industry Standard high performance Low Cement Castable), at CFB Boiler operating temperatures.

These products are now well proven with numerous much extended service references, the materials actually address the conditions in which they are working. In many respects this involved breaking some fundamental rules of Refractory Product design using such techniques as ‘Controlled Matrix Vitrification’.

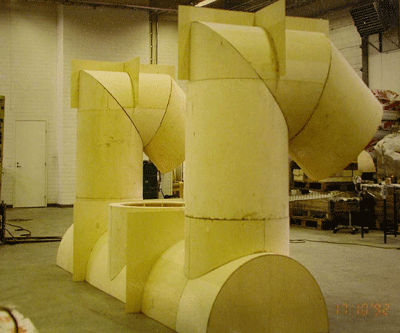

However, the challenge from AG Port did not stop here. They have a really intuitive system for lining boilers where all the Moulds / Shutters are preformed and delivered to the installation site ready for immediate construction and subsequent refractory installation. To enhance the obvious benefits of this system AG Port were also looking for materials with excellent installation characteristics. So Sheffield Refractories were no asked to produce their application specific CFB Boiler Materials but also to produce them as genuine Self Levelling, Pumping, (small bore pumping potential) and Shotcrete grades. With complex and intricate installations such as CFB Boiler Linings the installation characteristics of the Refractory materials are extremely challenging so a long and involved development process was required. Once again numerous successful installations have been completed including 4 CFB Boilers at the Petron Bataan plant in the Philippines, (200 t / hr). This was soon followed by the successful installation of refractory linings for 2 CFB Boiler in Indonesia for PT Cikarang Listrindo, (482 t / hr). The latest new build project was for FHI in IIoilo in the Philippines, a large 520 t / hour Boiler.

Sheffield Refractories is now working closely with Waste to Energy plants in the UK with a specific focus on developing innovation installation and materials technology. The company has the dual targets of achieving rapid repairs with a minimum of unit down time whilst also securing a subsequent extended period of service.